Our Products

WorkLink (e-permit)

Simplify and secure your maintenance operations with our all-in-one e-Permit Application System. Designed for industries like manufacturing, construction, oil & gas, and utilities, this digital platform streamlines the permit-to-work process—ensuring safety, compliance, and efficiency from start to finish.

✔️ Custom Permit Types – Hot Work, Cold Work, Thermal Power Plants, Manufacturing Industries, Electrical, and more

✔️ Built-In Safety Checks – Hazard identification, risk assessments, and safety protocols

✔️ Approval Workflow – Multi-level signoffs with real-time notifications

✔️ Audit-Ready Records – Complete digital history for compliance and inspections

From request to approval, manage every step digitally and securely reducing paperwork, minimizing risk, and keeping your teams safe.

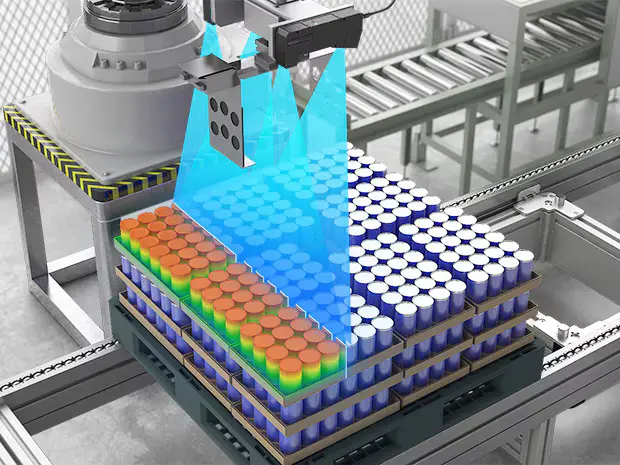

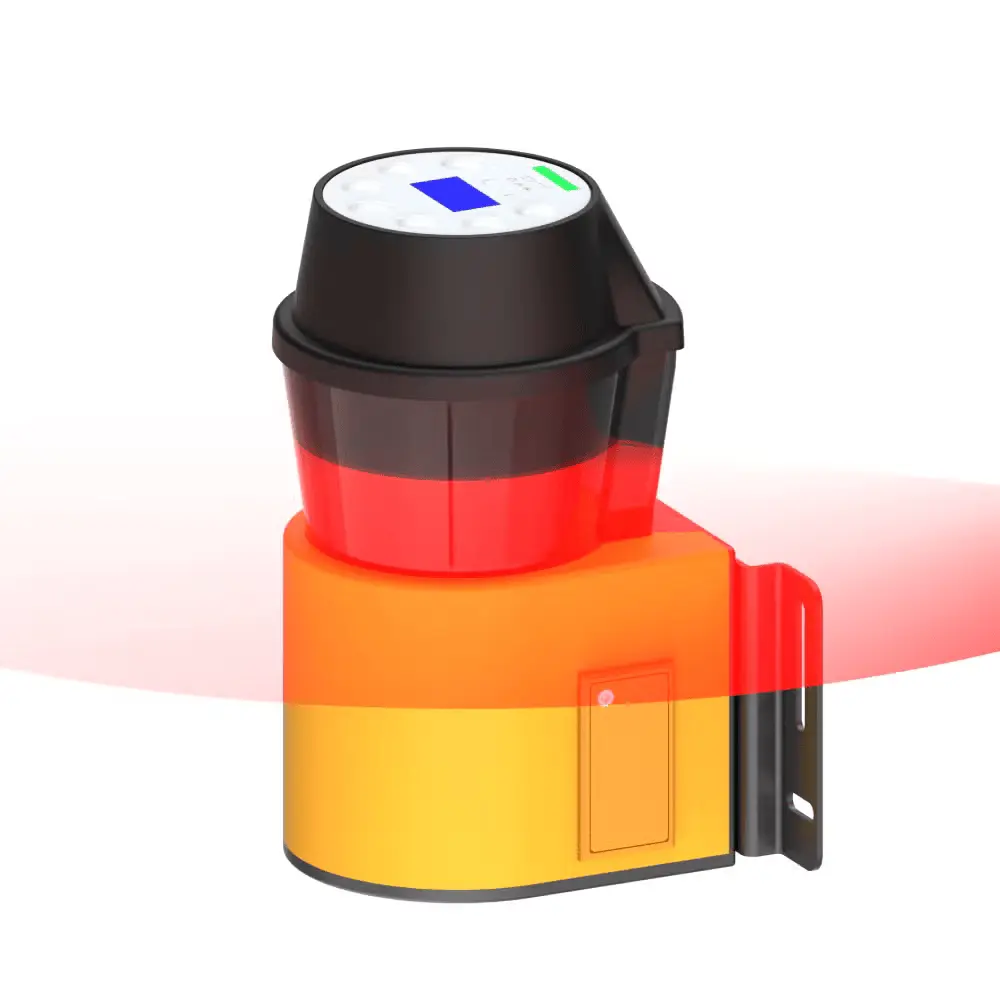

3D Profiler: flowSX

Precision Flow Monitoring with 3D Profiling

Our Volumetric Flow Rate Measurement Solution is an advanced, sensor-driven system designed to accurately measure the volume of bulk materials moving on conveyor belts in real time. Leveraging cutting-edge sensors and proprietary algorithms, the system continuously captures cross-sectional profiles and conveyor speed to calculate flow rates with exceptional precision.

Key Features:

- Non-Invasive Sensors – Utilizes laser, 3D vision, or ultrasonic sensors to detect material shape and volume without contact.

- Real-Time Analytics – Advanced algorithms process sensor data to compute accurate volumetric flow rates instantly.

- Seamless Integration – Easily interfaces with existing SCADA/PLC systems for full process visibility and control.

- Data Logging & Reporting – Continuous monitoring with historical trends, threshold alerts, and reporting capabilities.

- High Accuracy – Designed to perform reliably across varying material types, densities, and flow conditions.

Applications:

- Mining and minerals processing

- Cement and aggregate plants

- Agriculture and grain handling

- Food processing

- Waste and recycling operations

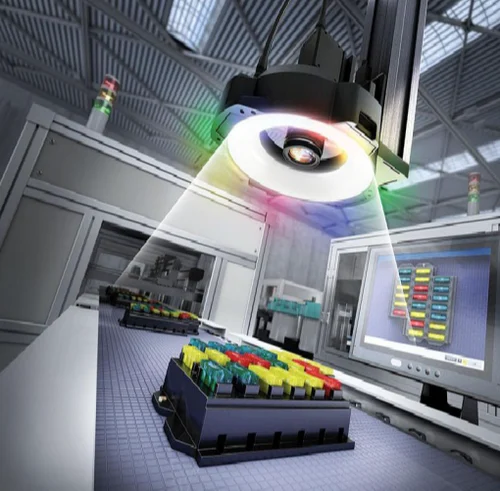

AI Vision Solution

| Integration of Artificial Intelligence (AI) and Machine Vision technologies in industrial settings to automate, monitor, inspect, and optimize processes. |

|---|

| Defect Detection | Detect surface defects, scratches, cracks, dents, etc., in real-time on production lines. |

| Dimension & Shape Inspection | Ensure parts meet required specifications using AI-based measurement tools. |

| Assembly Verification | Check whether components are assembled correctly (e.g., screws, labels, seals). |

| Object Recognition & Sorting | Identify, and sort items based on shape, size, or label using robotic arms or conveyors. |

| Quality Assurance (QA) | Automatically assess product quality, reducing human inspection errors. |

| Predictive Maintenance | Detect wear and tear in machines visually and predict breakdowns before they happen. |

| Safety & Compliance | Monitor PPE (helmet, gloves, etc.), zone breaches, or fire/smoke detection. |

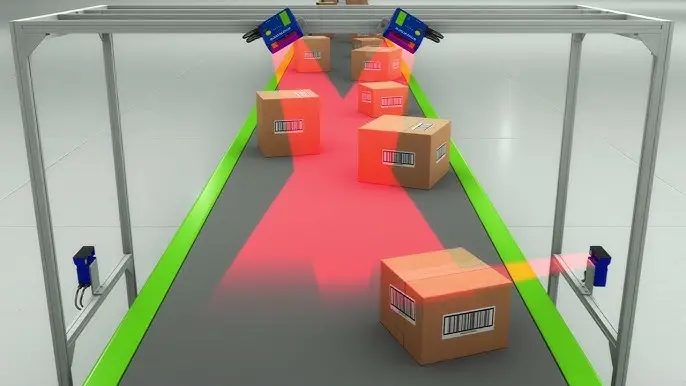

Bar-code/OCR

Industries We Serve

- Automotive

- Electronics & Semiconductors

- FMCG & Packaging

- Pharmaceuticals

- Food & Beverage

- Heavy Engineering

- Mining Industry

- Metal Industry

- Intra-Logistics

Vision Inspection Camera

3D Vision Camera

Safety Lidar/Sensor

Enhancing Industries through Advanced Automation Technologies

At Neuroflex, we engineer cutting-edge automation solutions that redefine productivity, precision, and performance across industrial landscapes.

Ready to embark on a journey of industrial transformation?

Let's turn your vision into reality. Contact us today to set your brand on the path to digital excellence with us.